What is an Energy Management System (EMS)?

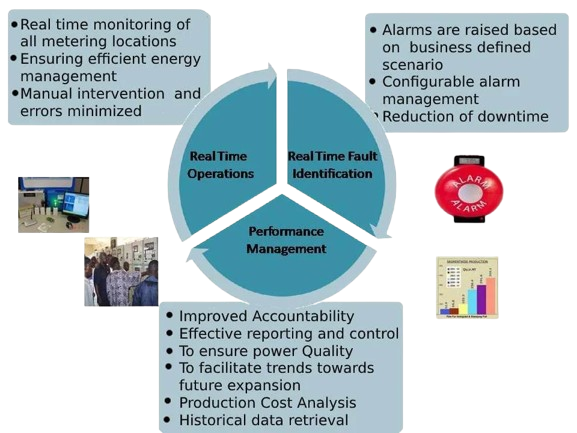

An EMS (Energy Management System) is an advanced platform that’s designed and built to monitor, analyze, and also optimize the energy consumption for industrial or commercial facilities. This provides real-time visibility for electrical parameters, helps in the identification of reduced energy wastage, and identifies inefficiencies while improving operational reliability. The combination of cloud analytics, IoT sensors, automated reporting, and EMS-enabled data-driven decision-making lowers energy costs and supports predictive maintenance. With the modern new-age monitoring system with major performance insights, companies can maximize system utilization and achieve long-duration sustainability goals.

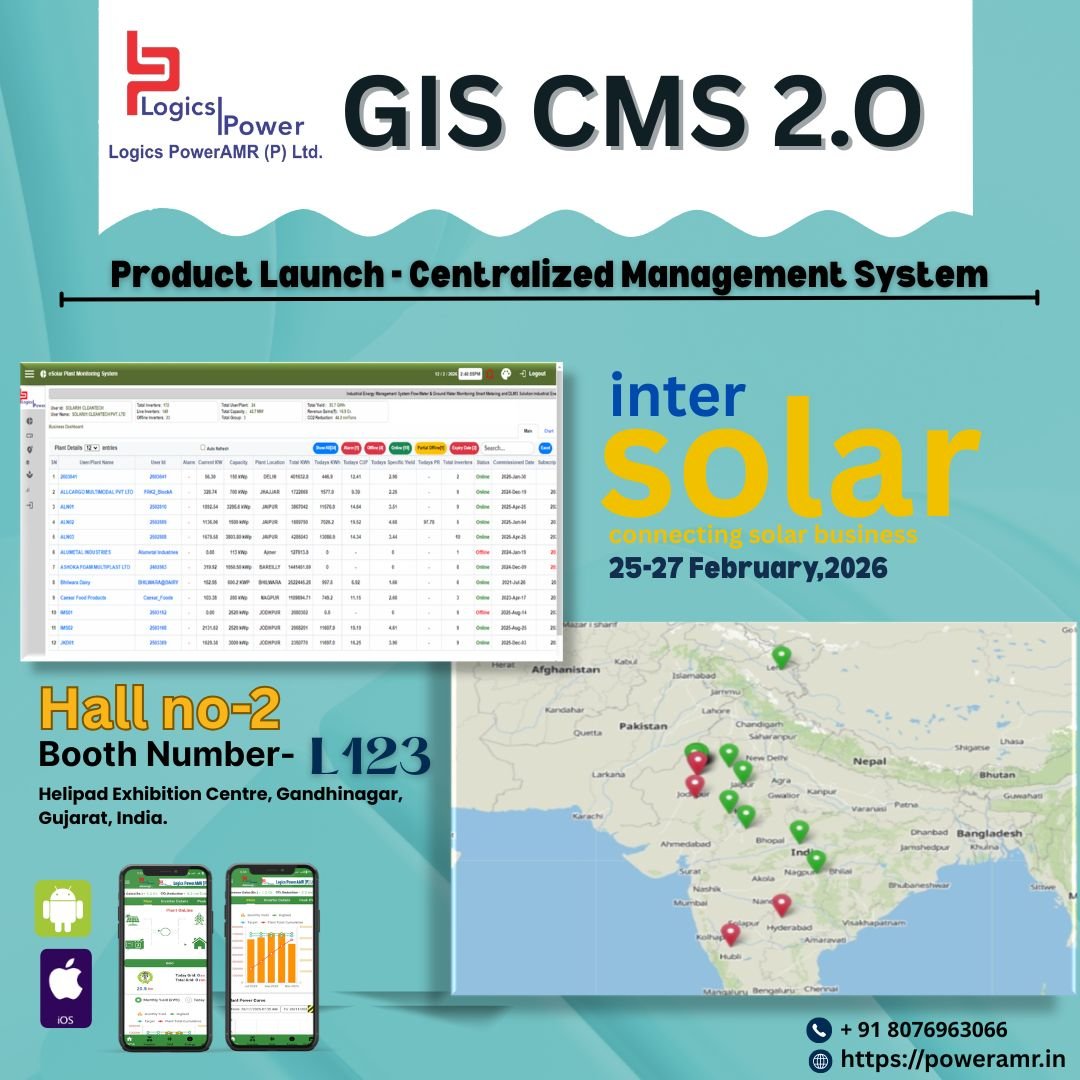

Download Technical Datasheet