Solar DG Synchronization Systems and Controller

Optimize the Solar Plant Yield and derive maximum benefit

DG synchronization with solar is a smart, automated energy management strategy where the diesel generator (DG) and solar power plant work together to meet total load demand efficiently. During solar hours, the system ensures the DG operates at minimum safe load while solar generation supplies the remaining energy. This setup prevents over-frequency issues, protects inverters from stress, and stabilizes plant operations even under fluctuating loads.

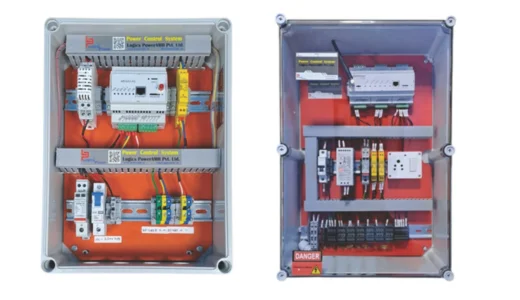

At Logics Power, our DG PV Controller ensures seamless solar DG synchronization, combining advanced algorithms, real-time monitoring, and intelligent load management to maximize solar utilization while minimizing fuel consumption.

Implementing dg synchronization with solar using a DG PV Controller provides clear advantages for plant operators, facility managers, and asset owners. It ensures stable operations, maximizes solar utilization, and reduces dependency on diesel.

Smartly distributes the total load between Solar and DG, ensuring the DG runs at the minimum safe load while solar covers the remaining demand.

Lowers diesel usage by allowing solar power to supply the majority of the energy required, resulting in substantial fuel savings.

Prevents excess solar energy from feeding into the grid, ensuring compliance with regulatory and site-specific restrictions.

Maintains stable plant operations by preventing reverse feeding, over-frequency issues, and inverter stress—ensuring longer equipment life and higher uptime.

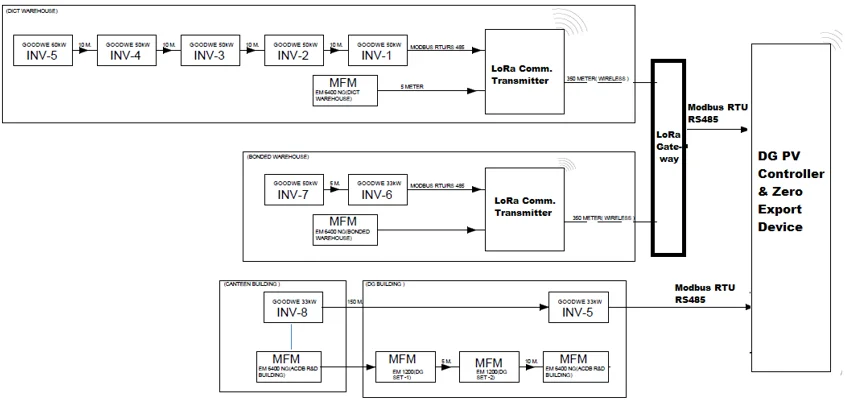

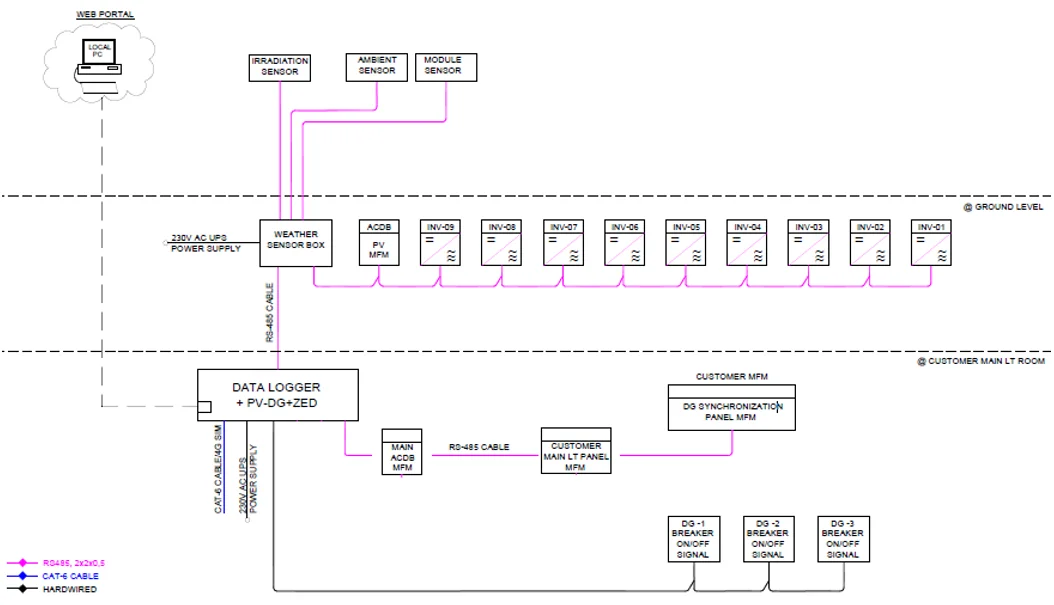

Wireless communication enables seamless DG–Solar synchronization without the need for long cable runs—ideal for large campuses, multi-building sites, and locations where wiring is difficult. With deep expertise in real-time Solar PV Monitoring for both rooftop and ground-mounted plants, PowerAMR delivers highly reliable wireless Remote Monitoring Systems that ensure optimal plant performance. Our platform provides continuous visibility, smart alerts, and accurate data to help operators maintain efficiency and reduce downtime.

When net metering is not available, solar power must be utilized strictly based on the onsite load. In such cases, synchronizing the solar system with the grid becomes essential. Through hardwired connectivity, the solar inverters take only reference voltage from the grid while ensuring that no excess power is exported. This enables safe operation, precise load matching, and full compliance with zero-export requirements.

Ethernet-based communication enables fast, stable, and highly reliable DG–Solar synchronization, especially in multi-building sites where a strong intranet network is available. Using this technology, the diesel generator (DG) and solar plant operate seamlessly together to meet total load demand with maximum efficiency. The system ensures that the DG runs at its minimum safe load while solar power supplies the remaining energy, resulting in optimized performance and reduced fuel consumption.

MQTT-based communication is ideal for large or multi-building sites where traditional wiring or network connectivity is not feasible. Using lightweight, cloud-ready messaging, each DG–PV controller communicates seamlessly through SIM-based connectivity, ensuring real-time data transfer and reliable DG–Solar synchronization across long distances.

Logics PowerAMR delivers cutting-edge technology designed to enhance the reliability, safety, and efficiency of Solar–DG hybrid systems. Our advanced DG–PV Controllers, Zero Export solutions, and multi-mode connectivity options ensure seamless operation across complex sites. With intelligent algorithms, robust communication architecture, and real-time monitoring capabilities, we provide end-to-end control that maximizes solar utilization, minimizes fuel consumption, and protects every component of your plant.

We follow a systematic, intelligent control process to ensure smooth DG–Solar synchronization, optimized inverter output, and stable plant operations.

The controller continuously measures the Active Power drawn from the DG through the installed energy meter to understand the current load conditions.

If the measured Active Power exceeds the defined Maximum Set Point, the controller automatically increases the inverter power to share the load and reduce strain on the DG.

If the Active Power falls below the Minimum Set Point, the controller reduces inverter generation to ensure the DG does not get underloaded and remains within its safe operating range.

This cycle repeats continuously, allowing the system to dynamically balance the load between Solar and DG. The result is optimized fuel consumption, stable DG performance, and maximized solar utilization.

Find answers to the most common queries below